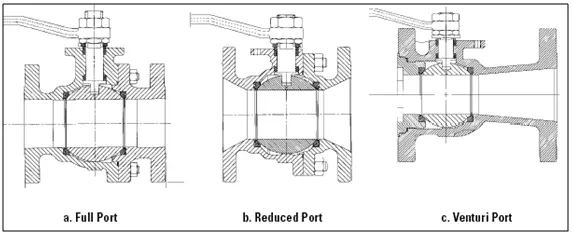

Differences Between Full Port Ball Valves VS Reduced Port Ball Valves

Full port ball valves provide almost no resistance to flow with the valve

Summary: The flow path via a full port valve body is identical size because the flow entering the valve and departing it via its tube or pipe connections. Reduced Port valves have smaller sized physiques overall having a corresponding narrowing within the valve body.

Introduction

Questions regarding the variations between full port or full bore valves and standard valves show up pretty regularly for all of us. I will attempt to answer a number of them within this publish. I have incorporated some related information by means of a brief FAQ list. These FAQs will help with a few of the intricacies and vocabulary. My intention is to supply a description from the variations between full port and reduced port ball valves and an introduction to ball valve type miniature valves.

What is a ball valve?

Generally, valves are devices accustomed to control the flow of the gases or fluids via a closed tube or pipe system. Flow via a valve could be relatively unobstructed when it's completely open. Flow stops once the valve is totally closed.

A ball valve includes a valve body having a rotatable ball inside it. This ball or sphere includes a hole or bore through its center. The handle on the ball valve opens the valve if this turns the ball to align using the pipe or tube that it is pointing exactly the same direction because the pipe. This enables flow to feed it. The valve handle may also turn the ball so the bore reaches the right position or 90 levels towards the flow. This closes the ball valve.

Find out more about full port ball valves

Ball valves are tough, durable and reliable. They close safely despite lengthy periods of not in use. These characteristics make sure they are a great option for shutoff and control applications. Ball valves are not able to supply fine flow control or throttling. Gate, globe or needle valves tend to be more suitable for these situations.

What is a full port or full bore ball valve?

A straight flow path

Little or no resistance to deal with flow

The flow path with the valve doesn't become narrower inside

The interior diameter from the pipe entering a complete bore valve is identical diameter because the flow path with the valve body and out through sleep issues from the valve. Most full bore valves are a couple of-way, quarter-turn ball valves.

What is a reduced port or reduced bore ball valve?

A straight flow path

Flow restriction creates a pressure drop

The flow path with the valve becomes narrower inside

A reduced bore valve body is one of the same diameter because the pipe or tube entering and exiting it. The significant area of the valve may be the ball within the valve body. Because the working area of the valve fits within the valve body, the bore with the valve ball is smaller sized compared to diameter from the valve’s connecting pipe or tube.

Listed here are some FAQs associated with valve basics, ball valves and selection tips

What are valve ports?

The ports of the valve are usually thought as the connections that carry the flow from the liquid or gas in to the valve and from it.

Exactly what is a two-way valve?

A Couple-way valve is any kind of valve with two ports or openings. The openings are often known as the inlet and outlet ports correspondingly. Two-way valves can be used for fundamental off or on applications however they may also be used for additional complex flow control. Ball valves are a kind of two-way valve.

Why are most of the ball valves the reduced port or standard bore type?

More compact design

Simpler and fewer costly to create

The main reason most ball valves use reduced bores is this fact design is comparatively compact. It's not unusual for space limitations to become a factor when selecting a valve. Standard bore valves also require less material to help make the valve body. Greater material and manufacturing costs could be significant once the body materials is one thing like stainless or Hastelloy.

What is a quarter-turn valve?

Ball valves are frequently known as quarter-turn valves

One fourth turn from the valve handle is sufficient to fully open or fully close one fourth-turn valve

Multi-turn valves require multiple turns from the handle to completely open or close the valve. Spigots around the outdoors of homes are among a multi-turn valve.

How come ball valves used so broadly?

Quick to open and shut

Obtainable in multi-port designs

Smaller sized and lighter than gate valves

Appropriate for neat and silty flow

They offer bubble-tight flow turn off

The range of ball valve designs and materials provides selection versatility

Able to reliable service both in high-pressure and-temperature applications

The pressure required to close ball valves is under for same sized gate or globe valves

Ball valves aren't perfect for controlling flow. It is because ball valves make use of a relatively soft ring-formed valve seat to produce a tight seal. When they're partly open, pressure is used to simply part of the valve seat. This could make the valve seat to warp and lower being able to give a good seal causing it to leak.

One more reason ball valves aren't great for controlling flow is they create turbulence and possible cavitation when used by doing this. Turbulence and cavitation reduce flow rates, increase noise and vibration and may even damage valves and piping.

What's flow turbulence?

Pressure difference across a valve may cause turbulent or irregular flow around the downstream side from the valve.

System conditions and valve design can increase or reduce turbulent flow. Generally, there'll always be some turbulent flow around the downstream finish of the reduced bore ball valve, especially when it's just opening and merely closing.

What's cavitation?

Flow results in a pressure difference across a valve. Rapid pressure drop across a valve may cause cavitation. Cavitation may be the rapid formation and collapse of vapor bubbles inside a liquid. At these times, the collapse of those small vapor bubbles could erode the valve and pipe material around them.

Pressure difference across a valve is larger for any reduced bore ball valve than for any full bore valve. Full bore ball valves generally have little or otherwise pressure difference over the valve.

What's valve bore size?

Valve bore size may be the size from the hole with the ball, the significant a part of a ball valve. The web site standard along with a full bore ball valve is proportional towards the size from the ball and it is bore. Full port bore sizes overlap with the interior diameters of both valve ports and also the pipe used. Reduced Port bore size is all about identical to the next smaller sized pipe size.

A good example to make this clearer

The bore inside a 3/4-inch size full bore ball valve is 3/4-inch across. The bore inside a 3/4-inch size reduced bore ball valve is 1/2-inch. It is because the balls in reduced bore valves are sized compared for their valve physiques and bore sizes. Used, this will make the bore diameter of the standard 3/4-inch ball valve about identical to the inner diameter of just oneOr2-inch pipe, the following smaller sized pipe size.

What's throughput and how is it associated with flow?

Fluids and gases flow readily in one spot to another with relatively low pressure. Calculating the flow of gases is a touch trickier than calculating liquid flow because gases could be compressed. Generally, though, the flow or throughput of the product is the level of fluid or gas that may go through it inside a given period of time.

What's flow coefficient (CV)?

The flow coefficient or CV is really a way of measuring the potential to deal with flow associated with a given a part of a fluid system. It's accustomed to calculate the size of straight pipe comparable to the flow resistance produced by an elbow or valve or other ingredient that affects the flow due to friction, turbulence or flow restriction.

A higher flow coefficient means a minimal potential to deal with flow along with a low flow coefficient means high potential to deal with flow.

A complete bore ball valve includes a low flow resistance (high flow coefficient), comparable like a straight bit of pipe. What this means is a complete bore ball valve causes hardly any pressure drop over the valve. The flow path via a reduced bore ball valve is narrower having a greater potential to deal with flow (lower flow coefficient). This potential to deal with flow leads to a bigger pressure drop over the valve.

Click This Link To Get To Know More About Our Ball Valves Product Ranges

Next: What Is Pump Flow or Capacity ?

Previous: What is Plug Valve ?