HOW YOU CAN SELECT CONTROL VALVES III

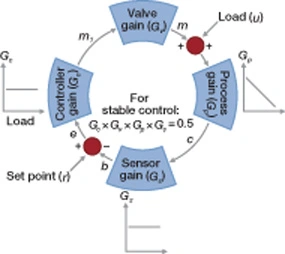

Most control loops are tuned for quarter-amplitude damping. This quantity of damping (decrease in the amplitude of succeeding peaks from the oscillation from the controlled variable) is acquired by modifying the controller gain (Gc = 100/%PB) before the total loop gain (the merchandise from the gains of all of the control loop components) reaches .5 (see Figure 1 below).

Increases of the straight line controller (Gv = plain proportional) along with a straight line transmitter (if it's a temperature transmitter, its gain is Gs = 100%/°F) are generally constant. Therefore, when the process gain (Gp = °F/GPM) can also be constant, a straight line valve is required to keep up with the total loop gain at .5 (Gv = .5/GvGcGs = constant, meaning straight line).

When the transmitter is nonlinear, for example within the situation of the d/p cell (sensor gain increases with the flow), it's possible to correct for your nonlinearity using a nonlinear valve whose gain drops with flow increases (quick opening). In the situation of warmth transfer more than a fixed area, the efficiency of warmth transfer (process gain Gp) drops as the quantity of heat to become transferred increases. To pay with this nonlinearity (stop by process gain = Gp), the valve gain (Gv) must increase with load. Therefore, the same-percentage valve ought to be selected for those heat-transfer temperature control applications.

FIGURE 1: WELL-TUNED LOOPS

Well-tuned Loops

Inside a correctly tuned loop, the decay ratio from the oscillation amplitude is constant at .25. Such decay ratio (?) is acquired when the product from the component gains (the entire loop gain) is constant at .5.

In the situation of flow control, one efficient way of maintaining your valve gain (Gv) perfectly constant would be to switch the control valve having a straight line cascade slave flow control loop. The limitation of the cascade configuration (additionally to the greater cost) is when the controlled process is quicker compared to flow loop, cycling will occur. It is because the slave in almost any cascade system should be quicker than its master. The only method to overcome this cycling would be to slow lower (detune) the actual by lowering its gain (growing its proportional band), which degrades its control quality. Therefore, this method must only be looked at on slow or secondary temperature control loops.

Positioning Positioners

A valve positioner is really a high-gain (.5% to 10% proportional band), sensitive, proportional-only, valve-stroke position controller. Its set point may be the control signal in the controller. The primary reason for getting a positioner would be to be certain that the valve does actually proceed to the positioning that matches the need for the controller output.

Adding a positioner can correct for such maintenance related effects as variations in packing friction because of dirt buildup, corrosion or insufficient lube variations within the dynamic forces from the processor nonlinearity within the valve actuator. Additionally, the positioner makes it possible for split-varying the controller signal between valves or can boost the actuator speed or actuator thrust by growing pressure and/or amount of the actuator air signal. Additionally, it may customize the valve characteristics through cams or function generators.

A positioner will improve the performance of all slow loops, like the charge of analytical qualities, temperature, liquid level, blending, and enormous-volume gas flow. A controlled process can be viewed as "slow" if it is the duration of oscillation is 3 or more occasions the time of oscillation from the positioned valve.

Positioners are also helpful to beat the "dead band" from the valve, which may be brought on by valve-stem friction. Caused by this friction is the fact that whenever the direction from the control signal is reversed, the stem remains in the last position before the dead band is exceeded. Positioners will eliminate this limit cycle by closing a loop around the valve actuator. Integrating processes, for example, liquid level, volume (as with digital blending), weight (not weight-rate), and gas-pressure control loops are vulnerable to limit cycling and can usually take advantage of the utilization of positioners.

Within the situation of fast loops (fast flow, liquid pressure, small-volume gas pressure), positioners will probably degrade loop response and cause limit cycling, since the positioner (a cascade slave) isn't quicker than the rate where its set point (the control signal) can alter. A controlled process is recognized as "fast" if it is the duration of oscillation is under three occasions those of the positioned valve.

Split varying of control valves don't always require using positioners because it's possible to also split-range the valves by using different spring ranges within the valve actuators.

When the requirement is simply to boost the speed or even the thrust from the actuator, it will install an aura volume booster or perhaps a pressure amplifier relay, rather of utilizing a positioner. When the goal would be to customize the valve characteristics on fast processes, this shouldn't be done through positioners, but by using dividing or multiplying relays within the controller output.

Smarter Smart Valves

Much improvement has happened and much more is anticipated in the style of intelligent and self-diagnosing positioners and control valves. The recognition and correction for that putting on from the trim, hysteresis brought on by packing friction, air leakage within the actuator, and alterations in valve characteristics all can be automated. When the proper intelligence is supplied, the valve compares its very own behavior using its past performance so when exactly the same conditions lead to different valve openings, it may conclude, for instance, that it is packing isn't correctly lubricated, or even the valve port gets plugged. In such instances, the valve can instantly request and schedule its very own maintenance.

A conventional valve positioner serves only the objective of maintaining your valve in the opening that matches the control signal. Digital positioners may also collect and evaluate valve-position data, valve operating characteristics and performance trends and may enable diagnostics from the entire valve set up. The control signals into smart positioners could be analog (4-20 mA) or digital (via bus systems). The benefits of digital positioners in accordance with their analog counterparts include elevated precision (.1% to at least one percent versus .3%-2% for analog), improved stability (about .1% when compared with .175%), and a wider range (as much as 50:1 when compared with 10:1).

Smart valves ought to be in a position to measure their very own inlet, outlet and vena contract pressure, flowing temperature, valve opening (stem position) and actuator air pressure. Valve performance monitoring includes the recognition of "zero" position and length of travel, actuator air pressure versus stem travel, and the opportunity to compare these against their values once the valve was new. Major deviations in the "desired" characteristic is definitely a symbol of the valve stuffing box being too tight, a corroded valve stem or perhaps a broken actuator spring.

Capabilities provided by smart valves range from the monitoring of packing box or bellows leakage by "sniffing" (using miniaturized chemical detectors), checking seat leakage by calculating the generated seem frequency, or by evaluating the controller output signal at "low flow" using the output once the valve was new. Another essential feature of digital positioners is the capability to affect the natural characteristics of the valve.

Valves Function as Flowmeters

A control valve may also be considered a variable area flow meter. Therefore, smart valves can measure their very own flow by solving their valve-sizing equation. For instance, in the situation of turbulent liquid flow applications, in which the valve capacity coefficient Cv could be calculated as the valve data may be used to calculate flow. This is accomplished by inserting the known values of Cv, Gf, ΔP and also the piping geometry coefficient (Fp) into the relevant equation for Cv. Naturally, to ensure that the smart valves for the future so that you can precisely measure their very own flow, they ought to be supplied with sufficient intelligence to recognize the relevant sizing equation for that particular process. (See Section 6.15 in Volume 2 from the Instrument Engineers"¥ Guide for valve sizing equations.)