KINDS OF PUMP CASINGS

Whether we’re speaking about volutes or diffusers, what all casings share is they are made to take energy by means of velocity and convert it into pressure.

Volutes

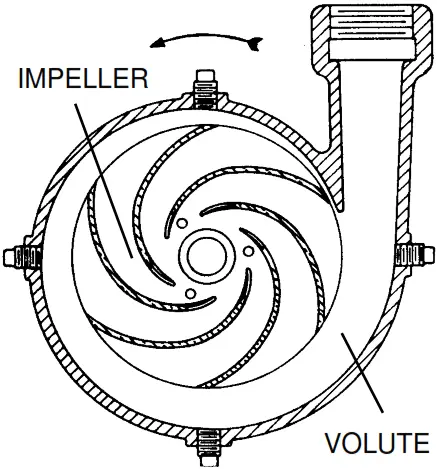

Volutes are made to capture the rate of liquid because it enters the outer diameter of the impeller and converts the rate from the liquid into pressure.

Within the picture right, observe that the impeller isn't located in the heart of the volutes. This really is intentional. The area of the volute that extends nearest towards the impeller is known as the cutwater.

You will observe, that beginning in the cutwater and proceeding in a counter-clockwise fashion, the space between your volume and also the impeller increases progressively. It has the result of causing pressure to construct inside the volute because the distance increases. Once the purpose of finest separation is arrived at - directly near the cutwater relocating clockwise direction - pressure reaches its finest, and water needs the casing if this encounters the cutwater.

Diffusers

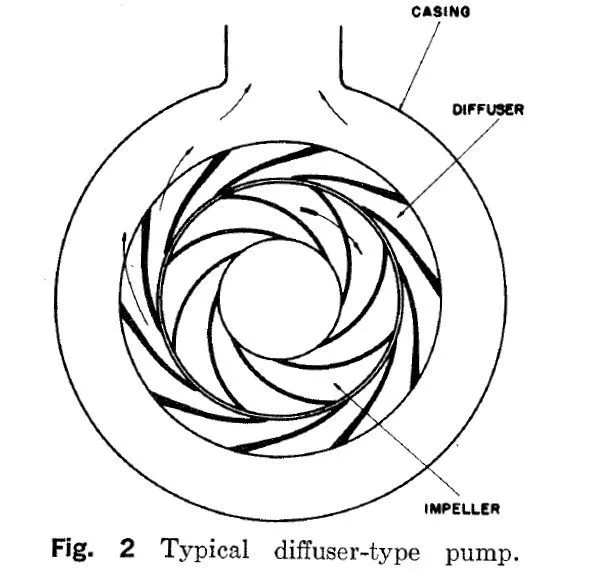

Exactly what a cutwater would be to a volute, vanes will be to a diffuser. While volutes have only one (or sometimes two) points in which the fringe of the casing approaches the advantage from the impeller to be able to begin building pressure, diffusers frequently have numerous vanes. Within the situation from the set up drawing proven the diffuser contains 10 vanes when compared with the volute casing which has only one.

Also, while an impeller is positioned in the heart of a volute, an impeller generally sits directly next to a diffuser and pushes water into the diffuser vanes.

The fundamental purpose of a diffuser is comparable to what volute. Diffuser vanes are situated so that they start near to the periphery from the impeller after which progressively extend from the impeller periphery.