Key Specifications / Features

Model No.: SJ-CP-01 Hits: 180

Detail Information

Stable running, low noise; No leakage

Application:

It is applicable for water supply and drainage in industries and cities, boosting water feeding of high buildings, garden irrigation, fire fighting boost, remote water- transportation, power station, residual heat utilization, metallurgy, chemical industry.

Specification:

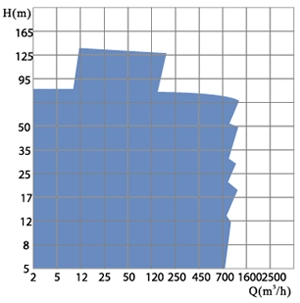

Flow Rate Q:2~1400m³/h

Head H:5~135m

Speed N:970~2950r/min

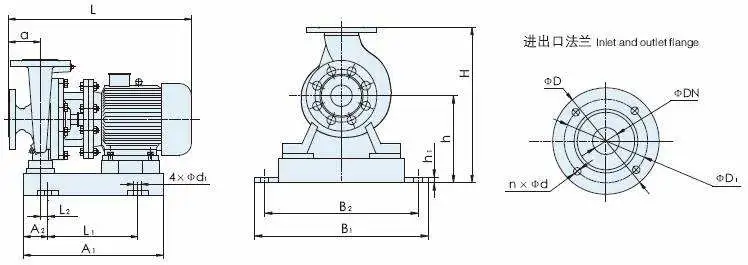

Caliber: Φ40~Φ350

Temp Range T:-15~+120℃

Service Pressure P: Max 1.6Mpa

Material: cast iron, stainless steel

Maintenance

a. The electric pump should be managed and used, and it is normal to check the insulation resistance between the electric pump winding and the casing.

b. Especially for each use thicker after a sticky slurry pumps should be run into clear water for a few minutes, to prevent the leaves sediment inside pump, electric pump clean.

c. Pumps if long time need not when electric pump should be removed from the water, do not soak in water for a long time, to reduce the chance of motor stator winding be affected with damp be affected with damp, increase the service life of electric pump.

d. In the condition of conventional pump for every 300-500 hours after use or replace the oil chamber will be listed in the oil (10 ~ 30 oil) keep good lubrication condition, mechanical seal to improve the service life of mechanical seal.

e. After the electric pump dismantlement and maintenance, the chassis component must be checked by 0.2 MPa gas tightness test to ensure the reliability of the electric motor.

f. The sealing ring between impeller and pump body has sealing function, such as sealing damage will directly affect the performance of the pump and should be replaced when necessary.