DOWNTOWN LOUISVILLE REPLACES VERTICAL TURBINE PUMPS, IMPROVING EMERGENCY TON RESPONSE

LOUISVILLE, KY, 12 , 15, 2017 -- Construction company Pace Contracting recently completed removal and installing three vertical turbine pumps, found in emergency flooding situations in downtown Louisville, Ky. Integral for the project were four 50-ton capacity Straightpoint (SP) wireless compression load cells supplied by Lifting Gear Hire (LGH).

Pace recognized a scope at your workplace within the Metropolitan St. Louis Sewer District (MSD), which partners with 59 municipalities (co-permittees) to evolve with stormwater permit needs for your St. Louis Metropolitan Small Municipal Separate Storm Sewer System. MSD billed Pace with jacking and remounting new substitute ton pumps, getting removed the old units.

LGH provided while in the hire fleet the obligation cells along with SP software (SW-MWLC) plus a rugged tablet. Pace also utilized a 10t capacity air hoist from LGH plus a 12-ton hoist throughout the gantry crane which had been permanently positioned in the structure from the pumps. The pump posts specified for to get placed in five sections, getting a complete weight of 28,350 lbs., which exceeded the capacity inside the 12-ton crane.

Michael Bryant, project manager at Pace Contracting, mentioned: "[Therefore], we'd to utilize the hydraulic rams from the base in the pump to assist the burden of four sections because the crane installed the fifth and final section round the primary floor. Once that piece was installed the reduced four sections were elevated up, when using the hydraulic rams, and so the pump could possibly be screwed together. The responsibility cells were extremely helpful simply because they helped us keep the center of gravity for your lower area of the pump centered, stopping it from tipping over."

The pump posts specified for for getting positioned in five sections, getting a complete weight of 28,350 lbs.

Pace utilized hydraulic rams within the base in the pump to help you the load of four years old segments because the crane installed the fifth and final section round the primary floor.

Dan Tobin, heavy rigging and lifting OSR at LGH, described that two major complications throughout the project were introduced on with this offset center of gravity cheap the physical kind of sight over the past 12 in. to 18 in. inside the jacking process was lost as soon as the pump assemblies were constantly in place.

The offset center of gravity round the 3.5-feet. diameter structures was because of discharge elbow midway within the suction tube setup. As described, the perfect solution is would have been to employ the obligation cells atop four LGH hydraulic rams, which possitioned on timber blocks, to weigh the 35-feet. suction tube and pump since it was come up with.

"We used the tare weight mode as well as set the burden sensitivity scale lower to twenty lbs. per jack point we programmed the alarm technique of additional safety," Tobin mentioned.

Pace safely jacked the supreme part of the entire setup through the use of SP's 2D center of gravity function to align the flange holes to the roof studs, despite only .5 in. of tolerance. Tobin mentioned he was experienced with the thought following consultation with Wayne Wille, technical sales director at SP, who introduced him to ale the product to demonstrate live, apparent readings, featuring 2D center of gravity, throughout the handheld device.

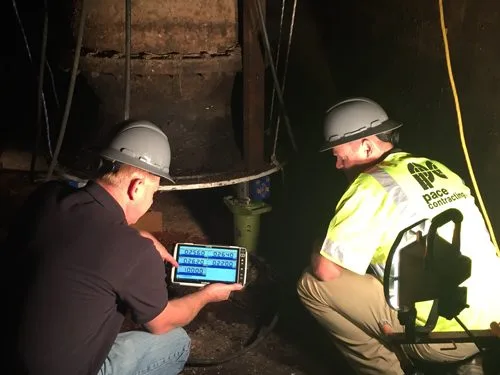

Load cell readings were adopted a rugged tablet.

Temporary lighting was forced to operate inside the undercover location.

He added: "I immediately saw the chance of recent and existing LGH rental customers which application offered just like a situation study that we'll use to assist show capacity."

Both operator and crew were safely somewhere safe to complete a few of the jacking jobs. "The whole solution was incorporated inside of a 3-week rental and saved eco-friendly tea's health benefits week in labor costs," Tobin mentioned.

Bryant concluded: "I had been very pleased with the solution presented by LGH the SP equipment was easy to use and truly plug-and-play. I had been grateful for your technology and expertise, given natural complications with working across the two-story building while in the downtown atmosphere, although working 50 feet. subterranean level."

About Straightpoint

Straightpoint, with offices inside the U.K. as well as the U.S., remains offering load cells to companies around the globe to ensure that their loads feel at ease to lift, offload, pull or push in excess of 4 decades. Straightpoint's merchandise is presently used within a collection of industries by way of example coal and oil, shipping, construction, renewable forces, lifting and cranes, mining, staging, ensure that inspection, and military applications. Goods are in the marketplace to book or buy.