Key Specifications / Features

Model No.: SJ-ECV-04 Hits: 53

Detail Information

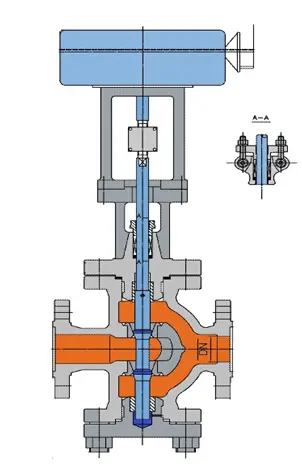

STRUCTURE FEATURES

| No | Part | Material | Material |

| 1 | Body | SA217 WCB | SA217 WC6 |

| 2 | Bonnet | SA217 WCB | SA217 WC6 |

| 3 | Stem | SS304 / 20Cr13 | SS304 |

| 4 | Disc | SS304 / 20Cr13 | SS304 |

| 5 | Seat | SS304 / 20Cr13 | SS304 |

| 6 | Packing | Flexible Graphite | Flexible Graphite |

2. The structure of the body is double seat type, the sealing surface applies with the double seat sealing, and the connection type is flange.

3. The disc is installed inside of the sleeve type seat, guided by the seat orifice. The valve adjusts the flow by up and down vertical movement by the disc; it has the advantages of anti-vibration, anti-abrasion and small leakage and so on.

4. The seat is designed to have many kinds of different flow passing area, which can meet many requirements of differential pressures.

5. The valve is easily to be disassembled, and the inside parts are easily to be replaced and maintained.

INSTALLATION

1. The valve must be installed on the pipeline vertically, connected with flange.

2. The flow direction on the valve body shall same to the installation direction.

3. In installation, the opening and closing position of the electric actuator shall same to the valve.

4. When clean the pipeline, some necessary measures shall be took in order to prevent the valve from sticking because of something left between the disc and seat, which may reduce the working life.

CONFIRMATION BEFORE ORDER

① Type (Including the actuator type, connect type, and material of the body and so on).

② Nominal Pressure PN (MPa).

③ Nominal Diameter DN (mm).

④ Working Pressure (MPa).

⑤ Pressure differential: Inlet pressure (MPa) and outlet pressure (MPa).

⑥ Working Temperature (℃).

⑦Cv value or the maximal flow rate (t/h).

⑧ Other technical requirement.

If the electric actuator is applied, the controlling signal shall be noted (0~10 or 4~20mA), if the pneumatic actuator is applied, bellow information shall be noted:

① If hand wheel is needed;

② Air filter pressure reducer;

③ Positioner, if it is the electro pneumatic valve positioner, please note the electric signal (0~10 or 4~20mA);

④ Air supply pressure;

⑤ Air-closing or air-opening.